| |

What they do:

The HID Ballasts have multiple functions – provide starting voltage or a high voltage pulse, regulating bulb current and power while providing appropriate sustaining voltage and current flow and manage power to optimize bulb life.

All HID ballasts must provide specific minimum starting voltage to ignite the bulb. In automotive applications, they provide a high voltage pulse that streams to the igniter, providing the immediate spark to fire the bulb almost instantly.

Ballasts also regulate bulb current and power. Following that initial pulse that sparks the bulb, the ballast limits the current to the bulb while operating. The ballast current is set to a level that provides proper power to the bulb. In addition, the ballast regulates the bulb current through the range of typical line voltage variations – or surges – maintaining stable bulb output and maximum performance.

A key function is the maintenance of the appropriate voltage and current wave shape to the bulb to achieve the published rated life. An increase in voltage to the bulb is typically required as the bulb ages. A well engineered ballast prevents the bulb from dropping out or cycling before expected rated life.

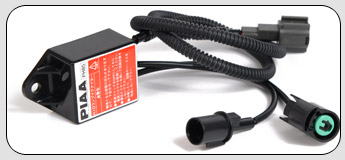

The PIAA Ballast:

PIAA has been involved with the development of HID technology for more than ten years. PIAA ballasts are engineered to start working at 7.9v and will shut down automatically if a surge exceeds 21.9v, which maintains the integrity of the entire HID system. This high maximum helps to prolong bulb life, as well.

The difference with lesser quality ballasts has been documented through in-house lab tests. These ‘comparable product tests’ show that some ballasts do not stand up well to surges in voltage and if a surge exceeds 16v, which can be common in today’s vehicles, immediate failure of the ballast can result.

PIAA ballasts exert greater control over electrical flow, meaning voltage output through the PIAA ballast is more consistent and stable, resulting in constant lumen output – consistently bright light with no flickering.

What they do:

The Igniter’s function is to ignite the bulb. A voltage spike of approximately 25,000 volts is coordinated from the ballast, providing almost ‘instant-on’ required for automotive use. The Igniter must be situated close to the bulb.

PIAA’s Igniter:

The PIAA HID Igniter is compatible with the ballast and the bulb, to ensure this significant voltage spike functions correctly. In some cases, cheaper kits use igniters from different factories that may not have sustained compatibility.

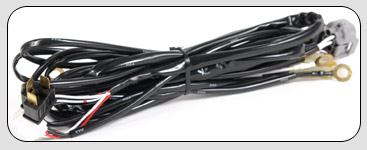

What it does:

Converts power from your 12 v battery to power up the HID system. All wiring features weather pak connectors to ensure flawless transfer of power. This ensures operation of the system from -40 C to +40C.

PIAA’s Harness:

PIAA’s Wiring harnesses are legendary for their ease of installation and ‘plug and play’ efficiency. The PIAA Harness is used to power the HID system and allows for use of the factory switches and daytime running light operations your vehicle was delivered with. Some vehicles require use of a 'patch' to override the computer and turn off warning lights, please see your dealer for details or email us for further information.

|

|

What they do:

The bulb function is to illuminate the road. Sounds simple. However, the HID bulb captures the electrical stimulus from the ballast and igniter and translates this into light output. This occurs when the electrical current passes through terminal plates positioned on either side of a gas filled glass bubble, igniting that gas in the bulb. The key difference between the HID bulb and a Halogen bulb is the absence of a metal filament wire.

The excellence of light output is achieved by exactly matching the arc point of the HID bulb with the filament positioning in a standard halogen bulb. This ensures the best use of the design of the headlight. If this positioning is off by a micron, the light scatters as it (insert) is out of synchronicity with the reflector and lens which help to control light output. This is highly annoying when you are driving towards a vehicle with ineffective HID's as it can be ‘blinding’. Behind the wheel looking forward, it is inefficient as the light is not on the road in front of the vehicle, improving your night vision.

PIAA’s HID Headlight Conversion Bulbs:

All PIAA HID Headlight Conversion Bulbs have arc points which match identically with the filament placement parameters on halogen bulbs. The placement of the arc point in the bulb is critical to the ongoing performance and durability of the bulbs.

This exacting arc placement ensures focused, effective and bright light output.

PIAA bulbs have a consistent gas configuration that ensures output color is identical between bulbs. So, you don’t have two different looking headlights.

PIAA’s HID bulbs, after that initial 25,000v arc to power up, run at 35w, which is significantly cooler than the halogen bulbs they replace. The output rating is closer to 150 watts.

PIAA bulbs were reduced in size, to accommodate better installation range, in the past couple of years. However, this reduction in size did not compromise inner components. One key component relating to bulb effectiveness is the length of the Molybdenum terminal plate, which conducts the electricity. PIAA’s plates are 8mm on both sides of the arc point. This size is critical because shorter plates we tested on competing products resulted in bulbs that failed in 200 hours or less. PIAA bulbs should light up your world in excess of 2000 hours.

|

|